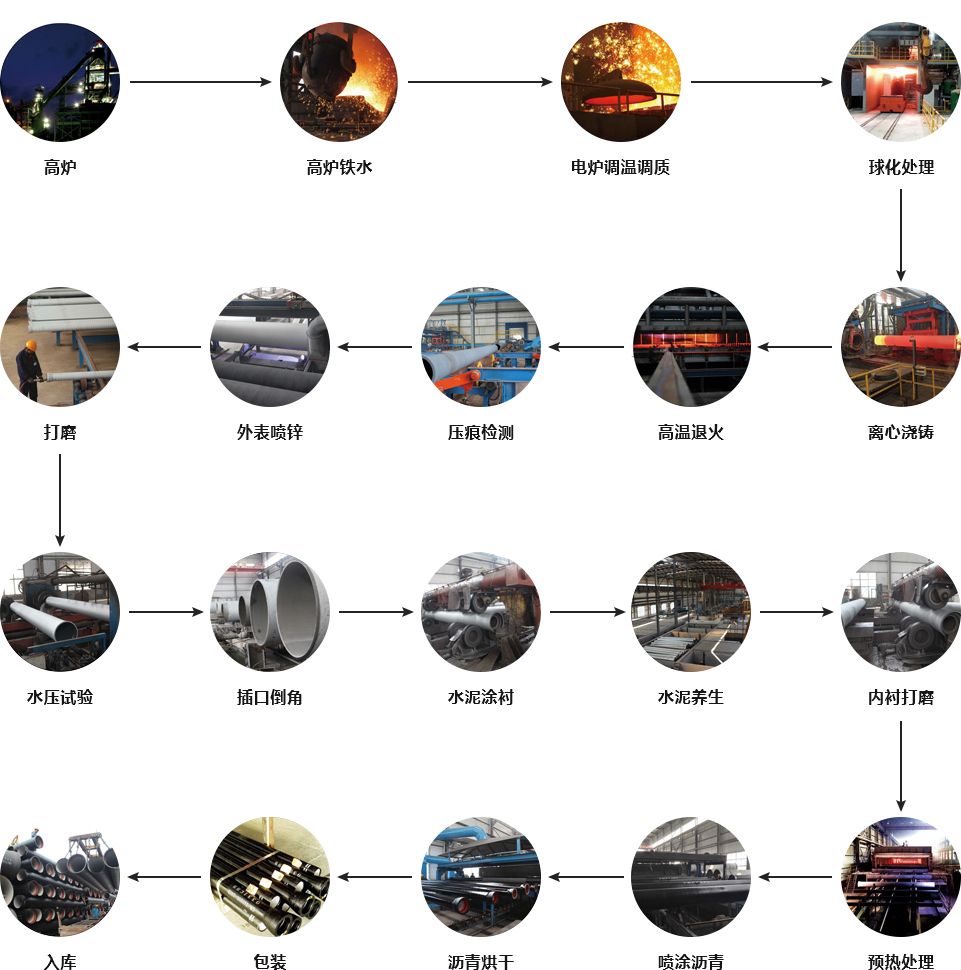

Product production process and production process flow

(1) The production Department is responsible for compiling the monthly production plan and organizing the production according to the plan to ensure the completion of the contract;

(2) The casting pipe workshop shall reasonably arrange the equipment maintenance and maintenance to maintain the equipment capacity;

(3) All departments and sections shall clean the environment, strict discipline, intact equipment, orderly logistics, accurate information and balanced production;

(4) The medium frequency furnace process should ensure the accuracy of blast furnace iron sampling, the iron composition and iron temperature of the medium frequency furnace meet the process requirements, ensure the accuracy of spherulized ferroalloy, and ensure that the iron supply for centrifuge to achieve "clean iron package, qualified composition, appropriate temperature and continuous supply";

(5) The analysis shall be true, accurate and fast, and the unqualified spectral analysis shall be notified to the medium frequency furnace; the analysis of the pipe test sample shall be true, accurate and fast, and the unqualified samples shall be notified to the process group in time;

(6) The centrifuge process shall be prepared before startup to ensure the continuity of production; supervise and inspect the molten iron in medium frequency furnace, return the unqualified molten iron and remove the slag during the pouring process; the agent shall be dry, stable and suitable to meet process requirements; the flow and drop trough shall be clean, smooth and non-shaking; the mold powder shall be dry and appropriate size; adjust various parameters and check before operation, and operate carefully during production;

(7) The annealing furnace should strictly implement the annealing process, and after the furnace should be strictly checked to prevent unqualified products from flowing into the finishing line;

(8) The refined zinc injection parameters should meet the process requirements, ensure that the quality of the three mills meets the standard provisions, and carry out hydraulic test according to the provisions, so as to make the test accurate, and clear identification;

(9) The cement lining process to ensure that the ingredients meet the process requirements, the lining layer quality is qualified, and strictly implement the health preservation process;

(10) The asphalt coating process shall strictly control the quality of internal grinding and chamfer, and the heating furnace furnace temperature and asphalt spraying parameters shall strictly implement the process standards, and achieve the accurate roll-over, clear identification;

(11) The core making process strictly controls the surface quality of the sand core to meet the standard requirements;

Product technical performance and configuration level

(1) Adopt centrifugal casting process

The pipe meets the requirements of ISO2531-2009 and GB / T13295-2019; anti-corrosion material shall be applied inside the pipe, the outer surface coating asphalt and arc zinc spraying meet ISO8179 standard, and the lining spraying cement mortar meets ISO4179 standard. Ductile iron pipe (pressure pipe) shall have a special equipment manufacturing license (grade B or above) and related identification materials.

(2) Inner wall of the pipe

The inner wall of the pipe shall be smooth and meet the ISO4179 requirements.

(3) Pipe connection mode

Slide-in (T type) rubber sealing ring seal interface.

(4) Grade of pipe wall thickness

Pipe wall thickness grade K9 grade.

(5) Quality of the pipeline

Pipe production process, especially the key process, the final product reaches the mechanical performance indexes proposed in ISO20531 and GB13295, such as tensile strength, elongation, size deviation, weight deviation, etc.; the zinc layer is 130g / m2, vent, double skin, neck casting defects, welding and repair of defective pipes; after appropriate heat treatment to achieve the required mechanical performance, pipe cutting, drilling, etc.

(6) The deviation requirements shall comply with the relevant regulations of GB / T13295.

1 Connection element deviation

The positive deviation of the external diameter of the pipe ends and pipe fittings shall not be greater than 1mm.

2 Wall thickness deviation

The wall thickness of pipe materials and pipe fittings is 6 mm, and the negative deviation is 1.3 mm;

The wall thickness of pipes and fittings is greater than 6 mm, and the negative deviation is (1.3+0.001DN) mm.

3 Length deviation

The standard effective length of each pipe of pipe DN1600 is 8.15 (6) m, and the maximum allowable deviation is ± 30mm;

See GB / T13295-2008.

4. Bearing port depth deviation

The depth deviation between T pipe and pipe fittings is ± 3mm;

5 For allowable weight deviation, see GB / T13295-2008. Supply is calculated according to the standard weight.

Weight of pipe is allowed for deviation

(7) Deviation of pipe fittings and accessories

The allowable weight deviation of bent pipe fittings and different pipe fittings is-12%; the allowable weight deviation of other pipe fittings and accessories is-8%; the positive deviation is not required.

(8) Straight

When the pipe is inspected by rolling on two platforms of about 2 / 3 of the pipe length, the maximum deviation fm shall not be greater than 0.125% of the effective length of the tube L, i. e., fm (mm) 0.125%L.

(9) Mechanical properties

The mechanical properties of ductile iron pipes shall comply with ISO2531 standard: tensile strength 420N / mm2, bending strength 590N / mm2,10% at diameter DN 1000mm, and 7% at diameter DN> 1000mm.

(10) Chemical composition

The phosphorus content of ductile iron pipe shall not be greater than 0.05%, and the sulfur content shall not be greater than 0.02%.

(11) Hydrostatic test

Ductile iron pipes and fittings shall be hydrostatic tested one by one before coating, and the test pressure value meets the contents specified in GB / T13295-2008 standard.

(12) Requirements for the lining of cement mortar

1 Cement

Cement used for lining shall meet the cement standards specified by the state.

Grinding: pipe diameter DN 1000mm is not allowed, pipe diameter DN> 1000mm is allowed.

2 Sand

The sand used in the lining shall be washed and distributed in clear particle size from fine to coarse. The particle size curve of the sand screened with national standards shall meet the following requirements:

(1) The fine particles (i. e., with a 0.125mm sieve through the mesh) shall not exceed 10% of its weight

(2) The large particle part with a maximum diameter equal to the lining nominal thickness 1,3 shall not be less than 50% of its weight.

(3) The coarse particle part (i. e., the approximate nominal thickness of the lining 2 and cannot pass through the mesh) shall not exceed 5% of its weight.

3 Water

The water used for the preparation of the mortar shall be domestic drinking water.

The ratio (mass ratio) of cement mortar shall be: cement: sand =1:1.5 ~ 3.0; cement: water =1:0.4.

4 Internal and external anticorrosion

All pipes, pipe fittings and accessories should be applied inside and outside, the surface of the pipe body coating requires cement mortar lining, the outer surface of zinc spraying, hot application and spraying asphalt paint, coating should be quickly dry and good adhesion, not peeling. The technical requirements of cement mortar lining pipe shall meet the ISO4197, "Pressure and Non-pressure Ductile Iron Pipe-Centrifuge Cement mortar Lining-New coated Mortar Material Control". External wall coating: apply zinc outside the pipe, using zinc content not less than 99% metal, spraying metal layer of zinc weight not less than 130g / m2, based on the zinc corrosion coating asphalt paint, implement ISO8179 "ductile iron pipe external coating standard", bearing to spray zinc anti-rust treatment process, spraying asphalt paint or epoxy resin paint average thickness is not less than 70um, the minimum thickness is not less than 50um.

(13) Mark-up

Each pipe, fittings and accessories shall have the following marks: a) Manufacturer, b) nominal diameter, c) production batch number (serial number).

Ductile iron pipe production process

Ductile iron pipe is a new generation of pipe developed on the basis of gray cast iron pipe, which combines the characteristics of corrosion resistance and wear resistance of iron as well as the flexibility of steel, which is called "the nature of iron, the performance of steel". Ductile iron pipe in nearly 70 years of development history and a variety of complex geological conditions in the engineering application of good performance, in many water pipe better, and gradually become the world's water supply and drainage field of safe and reliable pipe and won wide recognition in the world.

Production process of ductile iron pipe: using water and metal process for centrifugal casting.

Accessories production process: advanced vacuum disappearance die